- info@blumachines.com

- +91 98912 68568

BluMachines, New Delhi is a Leading Manufacturers of All Types of Stationary Machine, Food Processing Machinery in Delhi, NCR also in Quality, Certified ISO 9001-2015 and Tested Manual, Automatic and Fully Automatic Pen Making Machine Manufactures, Food Processing Machines in Delhi NCR, Noida, Ghaziabad, Faridabad, Gurgaon at Pan India, Owing to our highly productive manufacturing base Units and Staff for Installation in Haryana, Gujarat, Uttar Pradesh, Gujarat, Andhra Pradesh, Maharashtra, Tamil Naidu, Karnataka, Rajasthan, Uttrakhand, Himanchal Pradesh, Punjab, Kashmir, Odisha, Bihar, Madhya Pradesh, Kerala.

BluMachines is Reliable Manufacturer, Assembler, Supplier, and Trader, of Blow Molding Machine, Injection Blow Molding Machine, Paper Cutting & Making Machine, Chillers, and Blow Molding Machine etc. We develop these high standard machines as per the international parameters of quality that increases their market worth.

Introduction

Non woven poly bags are liquid resistant and offered in variety of patters. These can be used for regular purpose and manufactured to meet the requirements of the clients. They are designed in variegated patterns and following the latent trends to satisfy the end user and available in reasonable prices.

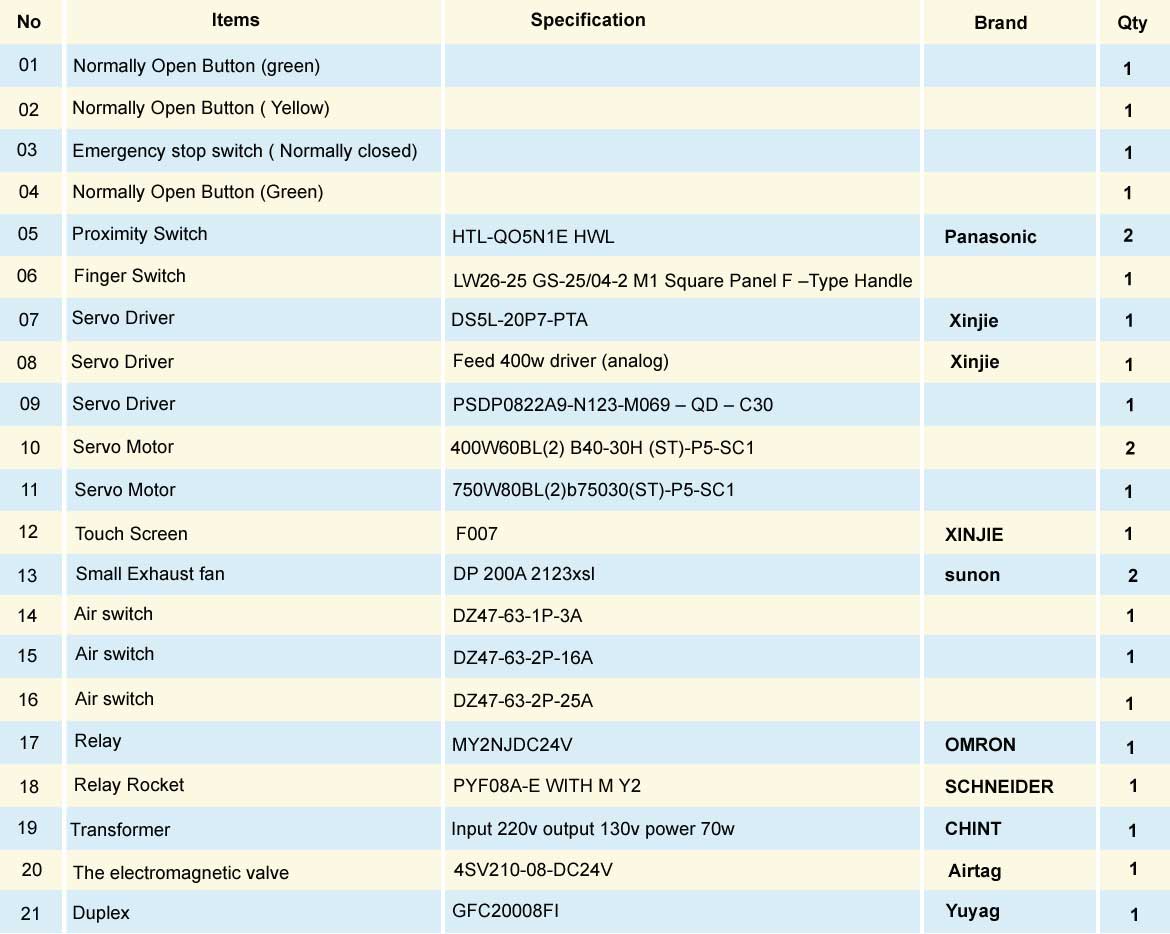

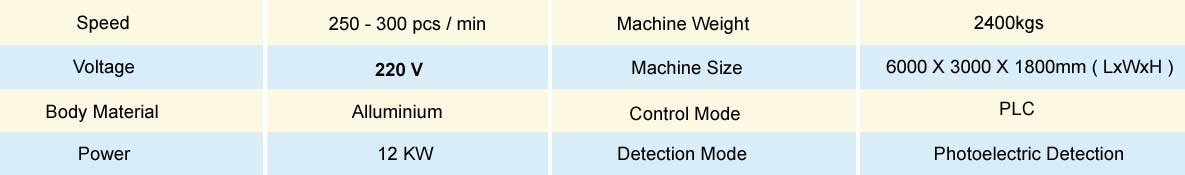

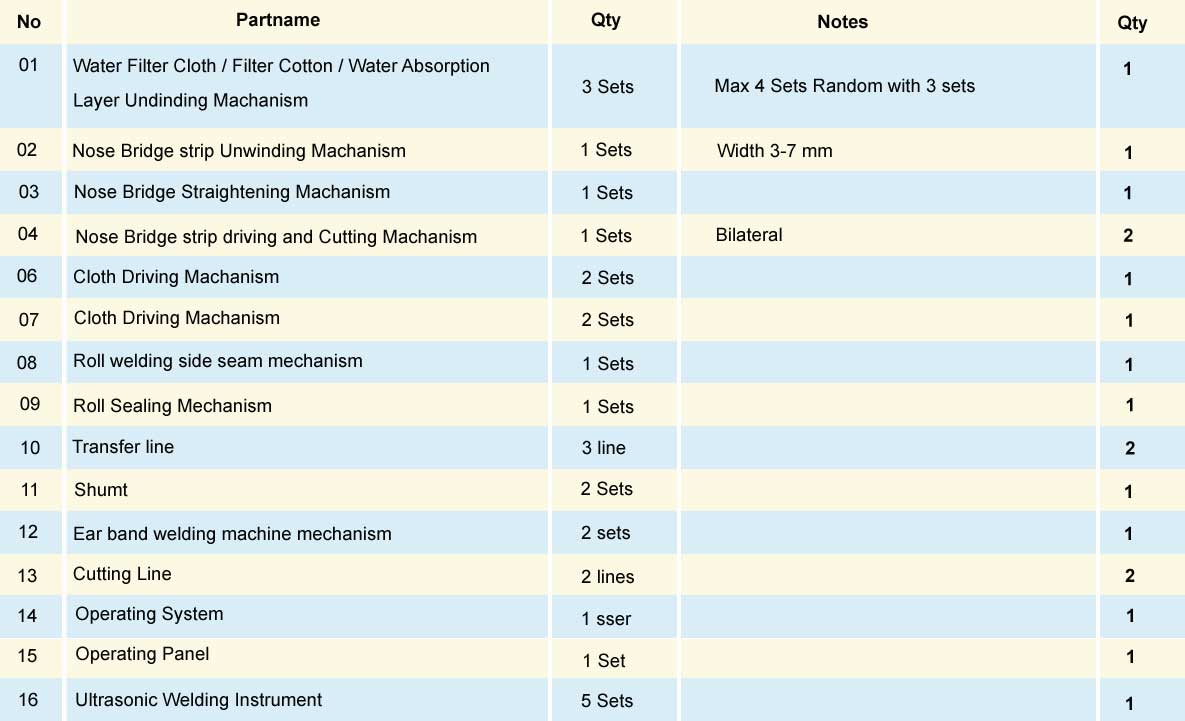

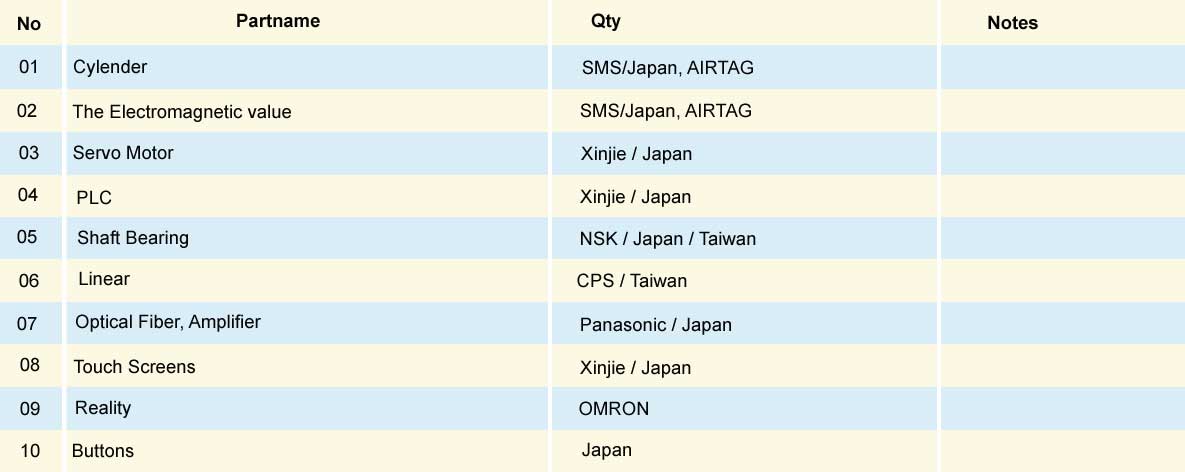

Medical Face mask Making machine Is the auto Equipment which be used to the product of disposable face masks, be suitable for the material of non-woven fabric, activated carbon and filter material from 1-4 layers. The face mask machine will finish all the processing from the feeding to nose- clip fixing, edge sealing, cutting the finished products automatically. According to different material you use, the finished products can reach the standards as 3ply, N95, FFP2 etc. This face mask machine has features as stable performance, high productivity lo error rate and easy operation etc.

A) Knife seal mechanism, rotary knife seal mechanism , 132 center distance ( double knife), straight grain, knife base length 180MM, knife base 4 strips.

B) Medium seal mechanism , the width of the support plate is 80mm ( suitable for wrapping the masks)

C) The tailstock is standard mid- mounted tailstock for small models with a length of 2.54m, the left and right movable panels are 250mm the movable apnel needs to be folded inside according to the height of the product.

D) The chain pitch is 250 , the push block is a stainless steel push block with a width of 15mm, the effective height is 25mm, and the height of the push block should be increased according to the height of the product , the discharge is standardwith a hair bruch and the length is 540mm.

E) HMI, touch screen operation.